About Global Lift Used Forklifts Scottsdale

Global Lift Scottsdale - Cushion forklifts are intended for use on indoor, smooth surfaces. They are either propane or gas powered with lift capacities of 1360 kilograms to 40800 kilograms. The cushion tire is constructed of rigid rubber. The compact body of the equipment makes it really suitable to maneuvering in tight quarters.

Pneumatic Forklifts are designed for both outdoor and indoor application and are suited for uneven ground. The tires provide shock absorption and better traction. The forklifts can be powered either by diesel, gas or propane fuel. They have the capacity to lift from 1360 kilograms to over 45000 kilograms. They can reach lifting heights of more than 9 meters. They are less compact as opposed to the cushion forklift.

Rough Terrain Forklifts are manufactured for rough ground, featuring a large chassis, high clearance and an ability to maintain stability when lifting heavy loads. They are powered by diesel, gas or propane. They are available in either 2-wheel drive or 4-wheel drive. Their lift capacities reach thirteen thousand six hundred kilograms.

The forklift is a material handling equipment used to lift and move loads from one location to another. Each and every forklift component has a specific function. Various components can be used to transport the load either vertically or horizontally.

The forklift mast refers to all the components which lower and lift the load. There are various types of masts for raising loads to various heights: triplex, quad, simplex and duplex.

Forklifts have four different ways of being powered: gas, electric, propane and diesel. The battery is located inside the cab under the seat. The propane tank is on the rear of the truck. The fuel tank on diesel and gas forklifts is underneath the back of the truck.

The forklift cab is situated within the center of the truck. This is where the operator sits and accesses all the controls and informational gauges. The steering wheel, gas pedal, tilting controls, brake and lifting controls are all situated within the cab.

Carrying all the largest forklift components is the frame of the truck. This includes the counterweights located at the back which prevents the truck from tipping over when loaded. The frame consists of the overhead guard that protects the operator. The undercarriage holds the axles, wheels and driveshaft.

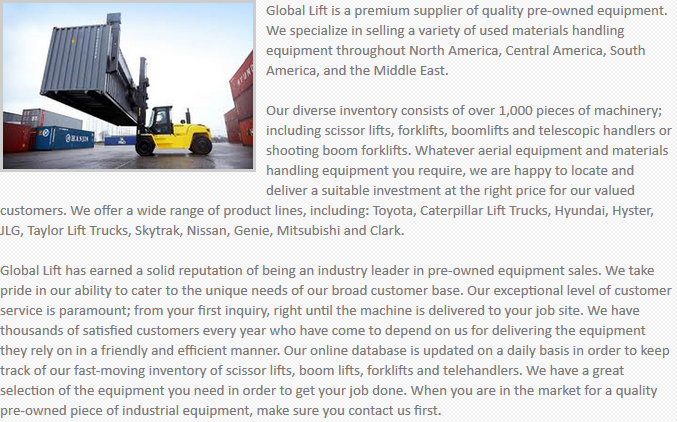

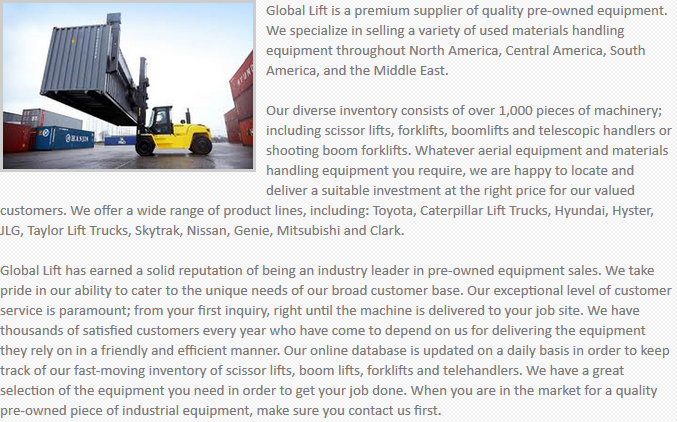

Powered lift trucks called forklifts are utilized in almost every industry to move heavy items and materials. The forklift is a very durable and reliable machine that has become essential tools in many warehouse and construction environments. Forklift units vary depending on the type of fuel that is used to power the lift truck and the type of work environment.

Electric forklifts are great for work sites that have limited ventilation since they produce no exhaust fumes and are fairly quiet. They are designed to be powered by large, industrial-strength batteries. Because the electric forklift batteries need charging, the worksite should have a charging station. The batteries are durable and can be re-charged up to 1,500 times before they need to be replaced. The charging station must be located in a ventilated area and include an emergency eyewash station and an acid spill kit.

Liquid propane powered forklifts are commonly used in modern industrial operations since propane has some advantages over diesel and electric. Propane models are cleaner to utilize compared to diesel-powered units. There is no down time required to recharge an industrial battery, and the cost for propane is less compared to the cost of electricity. A forklift propane tank can be refueled easily and quickly by changing out the empty tank with a full tank. Normally an off-site supplier refills the empty tank, making refueling really efficient and safe.

Diesel and gasoline forklifts are the machine of choice for outdoor applications and rough terrain. They are commonly found on lumber yards and construction sites. Their disadvantages comprise relatively high maintenance requirements, odorous exhaust and relatively high fuel costs. Their benefits comprise reliability in tough conditions and a longer lifespan than other units. Gasoline and diesel units must be refueled at a supply station on site which meets safety and health regulations.

Contact Info

Questions or Comments